2013 Caterham Superlight R300 Championship Brands Hatch GP round: Technical explanation of the alleged ineligibility

We have already explained the basis for an ineligibility report being filed. This update explains the technical aspects relevant to any decision as to part eligibility. It remains our robust position that there are no performance gains to be obtained from fitment of this part other than providing the driver with real time information on the Stack display as to coolant temperatures during the race. We also are firmly convinced for the reasons outlined below that fitment of this part is entirely consistent with that part of the championship regulation allowing integrated Stack data logging.

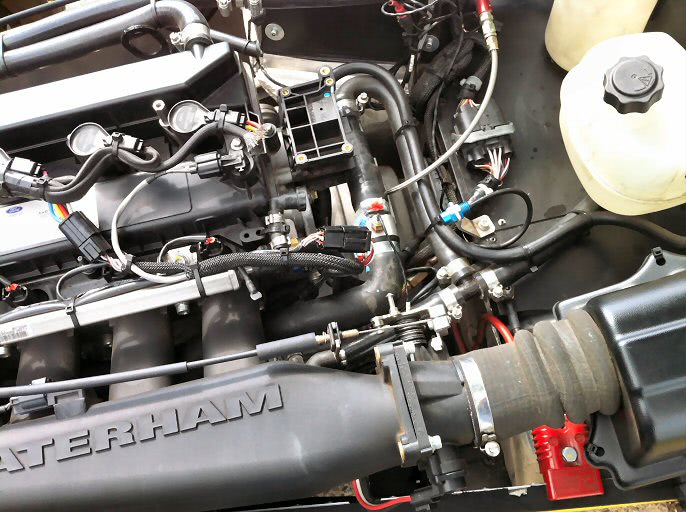

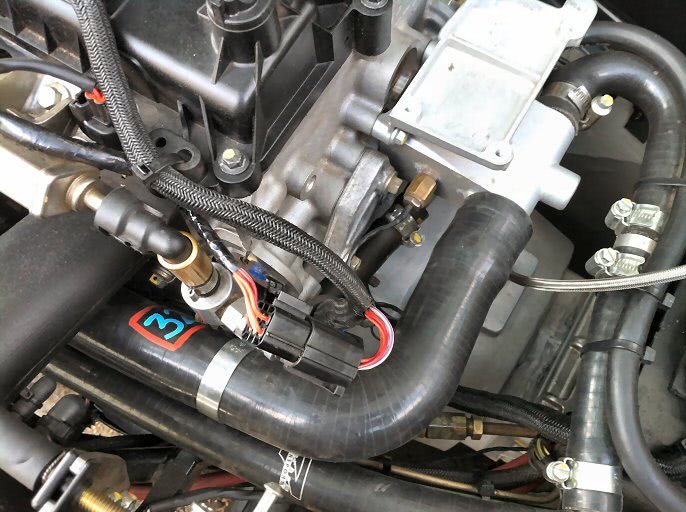

What part was the subject of the eligibility reportThe queried part is a standard off-the-shelf although non-Caterham supplied pipe joiner/sensor boss. This part was inserted into the top coolant hose to allow fitment of a Stack display water temperature sensor.

|

|

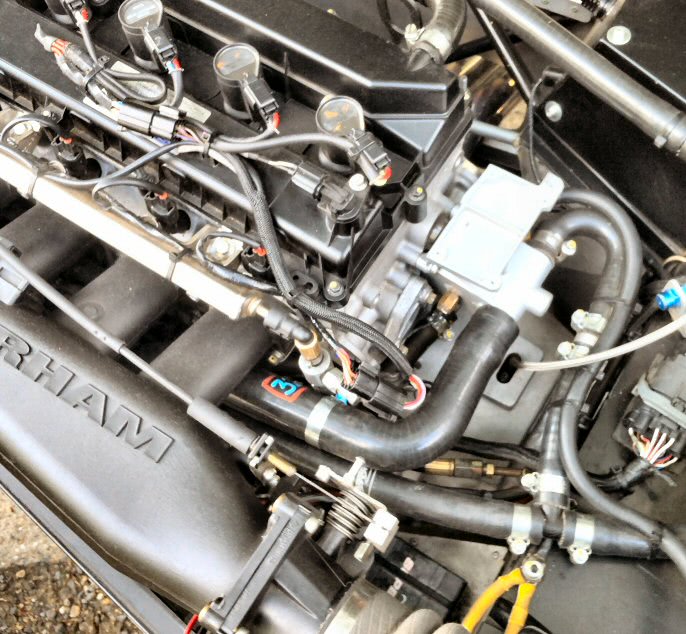

How visible was this part and for how long has it been on the carThe fitted part is immediately obvious and had been fitted to the DPR R300 since 2010 and subject to scrutineering examinations over 40 races with numerous scrutineering checks in pre race and post race examinations. The same part was fitted to the Aaron Head R300. Until this weekend this car has been looked after throughout the 2013 championship by the Caterham Motorsport support team who have carried out a gearbox change. To show that we have not altered any of the parts illustrated in this update, please note that the original MSA seals as added at Brands Hatch are still present. |

|

|

|

|

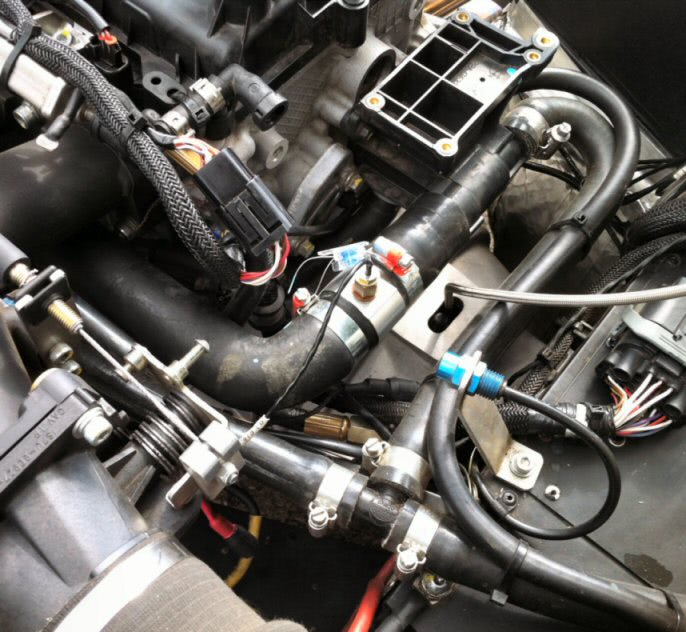

What does a system look like without this fittingThe picture on the right and below shows the under bonnet configuration for car 32 driven by Stuart Leonard that does not have the Stack take off mounted in the hose. This engine has the early alloy take off block which contains a fixing in the alloy block for a temperature sensor. This method of fitment is different to the later plastic take off block that has a Caterham supplied brass T piece into the smaller bypass water hose should that be considered a suitable point at which to insert a Stack display water temperature sensor.

In terms of coolant temperatures we have not seen any difference between the plastic block mounting point, the early Caterham alloy block and the pipe joiner/sensor boss method of fitment. |

|

Are there any implications for the Caterham programmed ECU response to water temperatureFor the avoidance of doubt this additional Stack display water temperature sensor has no connection with the car ECU and the entirely separate Caterham ECU temperature sensor. Therefore there is no possibility for readings from this additional sensor to have have any influence over the Caterham programmed ECU response to water temperature. The Caterham ECU temperature sensor is located on the other side of the take off block so is not apparent in these pictures. |

|

|

|

|

Does fitment of this part create a restriction that might alter the performance of the cooling system |

|

|

It is just not credible that fitment of this part could alter the heating efficiency for the following reasons:

Providing the driver with a real time display of coolant temperature and guidance as to how to reduce running temperatures will of course be highly relevant, particularly when slip-streaming in high ambients. This is a direct benefit from using integrated Stack data logging as specifically allowed by the regulations. The parts shown on the right with the original MSA seals will be available for all to inspect at Oulton Park. |

|

|

|

|

How does this part comply with the regulations given that only standard parts can be fittedThe 2013 championship regulations contain the following provision as follows: “For vehicles fitted with a Stack display unit, the use of a CAN ECU interface is permitted. The functionality for this is contained within the dash and is accessed via a PIN code provided with the ST8996 adapter lead required to make the connection. The CAN ECU interface enables recording in the data-logger of real-time data from the ECU, showing the actual output to the engine’s systems. Only Stack data logging and for integrated video logging, only Stack systems are permitted.” From discussion with Caterham, the following points are accepted

Our view remains that just as we are able to choose which Stack sensors should be fitted including the method of fitment and location this freedom applies equally to the Stack display water temperature sensor. If we do not believe the Caterham brass t-piece fitted to the bypass hose is an appropriate location for our data logging then we are free to position this additional Stack display water temperature sensor wherever we feel most appropriate and others can choose to do the same. |

|